News & Events

inMR Measure partners with Mimeo Industrial to expand objective eating quality traits for lamb

23 December 2025

inMR Measure is partnering with Mimeo Industrial to extend the range of objective traits measured for lamb eating quality.

The Australian industry is well advanced in commercialising a cut-based eating quality model, where key objective inputs include intramuscular fat (%IMF), lean meat yield (%LMY), and hot standard carcase weight. Together, these traits underpin more accurate predictions of eating quality and value.

inMR Measure uses magnetic resonance to automatically measure %IMF and through this new partnership, we plan to complement IMF measurement with %LMY, using non-contact microwave technology to measure fat depth at the GR site.

In-plant trials of the hand-held microwave unit have been completed and the next phase of the program will focus on a first installation in a commercial processing environment.

By combining automated IMF measurement with objective LMY assessment, inMR Measure and Mimeo Industrial aim to support eating quality models and help producers and processors unlock greater value.

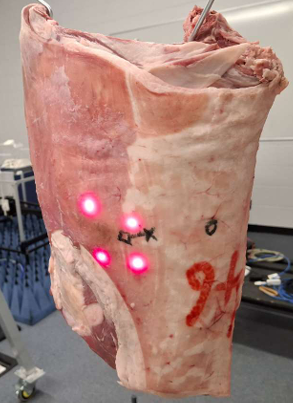

in-plant trials of the hand-held microwave unit, the four red LED markers indicate the measurement area.

An Update on our Fully Automated IMF Measurement and Live Sheep IMF

9 December 2025

We’ve released a new video showcasing our fully automated Intramuscular Fat (IMF) measurement system, featuring our twin Marbl™ sensors. The footage was shared by MLA at the recent MLA Update Event and demonstrates the system operating at chain speed, delivering accurate, non-invasive IMF grading in real time.

The video also highlights our progress in live-animal IMF measurement, including recent on-farm trials, demonstrating how Marbl™ can provide early insight into meat quality before processing.

Check out the video to see how we’re helping to drive the next step in meat quality measurement

inMR at the 2025 AMPC Innovation Showcase

17 September 2025

The inMR team had a great time sharing our latest developments at the 2025 AMPC Innovation Showcase. A key highlight was our twin-sensor lamb %IMF grading system, now installed at JBS Bordertown and running at main chain speeds. Reaching this milestone has taken significant work but represents a major step forward in delivering fully automated, non-invasive measurement for the Australian industry. For context, we mocked up the “heart” of the system, showing how the non-invasive measurement is made.

We also introduced our new sheep handling unit, designed to measure IMF on-farm. By gently lifting the animal off its feet, the system makes measurement simpler and more efficient.

AMPC certainly put on a great event, and we were delighted to participate.

inMR at the 2025 AMPC Innovation Showcase with a mocked up Marbl™ system.

inMR and Marbl™ Featured in MLA and Beef Central Articles

28 November 2024

It was great to have MLA, our earliest supporter, profile our recent trials of Marbl™ on live sheep and cattle. We’re looking forward to a continued partnership to bring our technology to the industry.

Thanks also to Beef Central for picking up the article as sharing our progress, and getting feedback from cattle producers, will help commercialisation. If you’re a producer interested in becoming an early adopter of ‘real-time marbling data’ we’d be keen to talk.

Marbl™ for Live Cattle IMF Measurement - Proof of Concept

26 November 2024

We’ve now wrapped up our first trials of a Marbl™ sensor for % IMF measurement of live cattle. We integrated the sensor into a handling crush and assessed the system for useability. The sensor was designed to measure 180cm3 within the shortloin and on a limited data set, accuracy was estimated at <3%. Significantly, the trials demonstrated that measuring IMF across various cattle breeds and sizes is feasible, showing the potential for Marbl™ to be used to grade cattle for IMF.

An Update on Intramuscular Fat Measurement for Live Sheep

26 November 2024

Following the completed proof-of-concept project with MLA, a report on our work is now available. In brief, we’ve shown that with accurate positioning of the Marbl™ sensor, measurement of IMF in live sheep is possible.

We’re excited to embark on the next step of this journey. Successful commercialisation will provide confirmation of genomics around IMF, an eating quality trait.

Live Cattle %IMF results being presented at MRPM 2024

27 August 2024

Our Live Cattle IMF measurement work is being presented at an international NMR conference this week. The abstract for the work can be found here. In brief, the overview is as follows.

The Live Cattle bespoke Marbl™ sensor was fitted to a modified crush and was designed to measure within the highly-valued shortloin. As seen in the photo, the sensor is large. We needed the size to measure within the muscle – similar to an MRI. A volume of 140cm3, starting about 20mm beneath the skin, was being measured with this sensor design.

Being a prototype system, refinements were required to get to the first results. Beyond that, animal movement was a dominating factor. This wasn’t unexpected and although we had a setup to manage movement, animal throughput was set by other doing routine animal monitoring. So, on average 3 minutes to get the animal in, settled and measured. Not bad in itself.

There was sufficient decent data to demonstrate the potential when compared with parallel gold-standard chemical IMF measurements after slaughter. Chemical IMF ranged from 3-15%.

There is more work to do, but for context, it was only 3 years ago when we were in a similar position with our lamb carcase-grading Marbl™ sensor. That sensor is now proven in-line, in a processing facility. So, this feels familiar.

Finally, thanks to MLA for co-funding this work. Our final report will be on their website soon.

Marbl™ in action on a live cattle - looking back

Marbl™ in action on a live cattle - looking forward.

Exciting Update: Marbl™ Trials Show Promising Results for Measuring Marbling in Lambs

9 August 2024

Want to know an animal’s IMF levels before processing? Well, our recent on-farm measurements of lamb bring that one step closer.

Using our non-invasive Marbl sensor and two trial setups, we verified that when the sensor is well positioned, the results were good. Each animal was measured in 10-15 seconds once in position.

The shearer-setup delivered the best results on the day, but we're targeting the handler-style setup, with Marbl™ on the spring-balance, for further work as it should prove more reliable and consistent in the long run.

Check out our video showcasing both methods in action and stay tuned for more updates as we continue to refine and enhance Marbl™!

Hot grading of lamb using IMF – the learnings, 1 year on

10 July 2024

It’s approaching 1 year since we installed our first single Marbl™ sensor at Ovation’s Gisborne processing plant for hot-grading lamb carcases for Intra Muscular Fat (“IMF”), so what have we learnt?

First some results and context. Nearly one year on, we’ve found the average IMF varies by day. Now, close to the end of this NZ season, the daily average is typically from 3.5 to 4% IMF, and each day there are a portion of animals measuring in the 5 to 7% IMF range. For context, this compares with a scientific study in 2014/2015, where the mean in a NZ study was 2.7% IMF and the range 0.9 - 6.4%.

More on the data in future posts, but for now; what are the learnings for a start-up business in making this happen?. The top key learning is an experienced team, partnering and good design have ensured robustness and success.

To our knowledge, this is the first magnetic resonance system operating in such an ‘industrial’ application for routine measurement. We expected challenges as our risk-register was initially long. The top few risks were around not impacting plant production, meeting the required cycle time (4-5 carcases/minute), managing electromagnetic noise interference and ensuring durability and robustness for the volume of carcases and daily washdown. One year on, we’ve worked through and managed them all. But most significantly, the Marbl™ sensor, has worked a charm. Being a first of, we’re chuffed with the system and it’s performance. A credit to the career-long, applied NMR skills of Evan McCarney and Robin Dykstra (in our team), combined with a well-designed spectrometer from Resonint (another credit to Robin) and the engineering capability of Advanced Engineering Solutions.

Also, we could not have taken magnetic resonance to this application without the benefits of automation. Measuring by carcase, with thousands of carcases processed daily, automation ensures that the measurements are made without the need for any labour input.

Finally, we could not have achieved this without the support of Ovation New Zealand and Sustainable Food and Fibre Futures.

Marbl™ in action on a lamb carcase.

Marbl™ & Live Sheep - Part 2

23 June 2024

Here’s our alternate test setup for IMF measurement of live sheep. Marbl™ was positioned over above using a gantry-style frame and spring-balance, with the lamb being positioned in a sheep-handler.

A bit of ingenuity was required when we found the frame of the handler prevented access to the backstrap when we positioned our first ever lamb. Nothing a few extra hands couldn’t cover off after removing one side of the sheep handler, we got the job done.

This early field work suggests this method gave us better positioning and with the animals having been processed, we can now measure IMF in the meat. On the plus side, as the photo of the meat shows, we know there was a range of marbling!

Positioning a lamb within the handler.

Handler and sensor within the run.

Examples of the range of marbling within the lamb.

Marbl™ & Live Sheep - Part 1

20 June 2024

An interesting few days in Gisborne! After setting up on-farm on a balmy 20C winters day, we ran a variety of lambs through our two setups for measuring IMF using Marbl™ on a day pouring with rain.

Here's our "shearer-style" setup - before and in use. A big focus on animal handling with a bit of effort being required to position the animal to align the sensor on the backstrap - but achievable.

However, early preference is the adapted sheep-handler - keep an eye out for more on this in part two coming soon!

Adapted sheep-handler setup on-farm.

A lamb being positioned within the sheep-handler and sensor.

Our IMF Backstory – in brief

24 May 2024

To date we’ve specialised in non-invasive IMF measurement. From 1% to over 20%, lamb or beef, hot or cold, we’ve measured it with our Marbl™ sensors and referenced to a gold standard infrared laboratory method.

The lamb loin photos show the variation in IMF coming through a processing plant in a day of testing using our hot lamb grading system. We were selecting for IMF range to validate our system.

The beef striploin photos show a variation from 2% to 22%IMF. We’ve measured this range both in a lab and alongside the boning room conveyor belt. For the latter, we rolled our mobile Marbl™ unit into a boning room and selected and measured striploins from the belt. Measuring over 20% IMF, or above marble score 9, is also possible as we directly and quantitatively measure the fat.

So, we’ve got the range of IMF covered and in addition we measure hot (live animals or recently slaughtered animals) or cold (carcases from the chiller, or primals from the boning room). This gives us the option of using the same sensor along a value chain. It’s the ‘hot’ verification work that underpins Marbl™ live for cattle and sheep.

With the support of AMPC and MLA, we continue to work on key proof points and demonstrate the accuracy and versatility of magnetic resonance.

Examples of lamb loin IMF. Left 3% and right 10%

Examples of beef striploin IMF. Left 2% and right 22%.

Live Cattle IMF Measurements - An update

1 May 2024

We’re doing it – measuring intramuscular fat of live cattle!

This is an exciting new application of Marbl™, but not too far from our hot carcass IMF grading and beef work. The photo shows our prototype Marbl™ Live sensor in use, making our MRI-like measurement. We directly measure the intramuscular fat; no image analysis is needed.

Going forward we will continue measuring more cattle and referencing against gold standard laboratory %IMF measurements. Our goal is to achieve objective IMF measurement for producer decision making.

Thanks to Meat & Livestock Australia and University of New England for their support. Follow us to track our progress.

Prototype Marbl Live™ sensor in use, measuring cattle IMF

Automated IMF at 8-12 carcases per minute - our next step

26 March 2024

We are pleased to announce we’re underway with realising hot, automated IMF measurement for higher throughput lamb-processors. Our concept includes twin-Marbl™ sensors and pairs of carcasses being measured at the same time to accommodate chain speeds of 8-12 carcasses/minute.

AMPC & MLA are supporting a project to demonstrate this system, in use, on the main chain, in a processing facility in Australia.

If you’re a processor targeting MSA eating quality pathways and are keen to be involved, then please contact AMPC with an expression of interest.

Twin-Marbl™ Sensor Prototype

Hot-lamb %IMF grading: over 100,000 carcasses automatically measured

15 February 2024

Are you a lamb producer/processor who wants to differentiate product but has been constrained by equipment and staff to operate it? Our new automated system may be the solution.

Following our trial-project announcement in March 2023, we’ve proven our system and validated IMF measurements in-line, across two seasons. Over 6 months we’ve measured well over 100,000 carcasses at the end of the slaughter-floor.

Our single sensor system is suited to processors operating at chain speeds of 4-6 carcasses/minute. As the system is fully automated, if staff numbers are down, no compromising on value-adding data.

We’re doing a soft launch of our lamb system and wish to talk with interested processors and producers who want to position their top-end product above the rest.

A system for faster chain speeds and equipment accreditation is a work in progress so follow us for further updates!

Live Cattle IMF Measurements - On it’s way!

7 February 2024

It’s been a mission but we’re excited to soon be trialing our new, prototype gear to measure the IMF of cattle. Here’s a photo of the gear all packed down into the base of our modified crush.

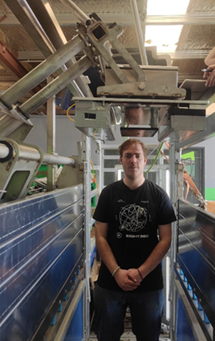

And, before packing down, this is what the system looked like. Here, you can see “Marbl™ Live” in its rest position, fitted to a sensor mount and manipulation assembly. Anthony, our technician, stepped into the photo to provide some context of scale. With our prototype and our in-line lamb work, we’ve shown our Marbl™ sensor can accurately measure %IMF, and we’re looking forward to working with a wider team including Advanced Engineering Solutions and the University of New England to make our MRI-like measurements. Thanks to Meat & Livestock Australia for their support of this project.

Marbl™ Live packed down into the base of a modified crush

Anthony standing within the Marbl™ Live

inMR's sharing with the International Science Community

5 October 2023

Were you aware that our automated, non-invasive intramuscular fat (IMF) lamb grading system is taking magnetic resonance into new territory? We're leveraging its maturity and accuracy as a proven method, it's speed and robustness to tailor it's use in the meat industry.

Over the last month, we've proudly shared our new application of magnetic resonance internationally. Our CTO, Evan McCarney presented our work on the hot lamb grading at the International Conference on Magnetic Resonance Microscopy Materials, Molecular Processes and Engineering in Singapore, and our Technical Director, Robin Dykstra responded to an invitation to publish a peer-reviewed paper titled Automated Eating Quality Measurements on Lamb Carcasses in a Processing Plant Using Unilateral NMR (published in Applied Magnetic Resonance).

In a scientific domain where much is known, it's exciting to be pushing the boundaries and that's the feedback we've received. With time, we'll be taking the technique further, from IMF measurement of carcasses to IMF measurement of live animals and then, to other meat-eating quality traits - there's a lot of additional information in a magnetic resonance signal and we're only getting started.

We've just opened our LinkedIn account, so click below to stay up to date and follow our progress.

Marbl™ for Live Cattle

4 September 2023

inMR is broadening the potential of the Marbl™ non-destructive IMF sensor, from use for hot lamb carcass-grading to live cattle. This work has the support of MLA and was a successful response to a call for tender to develop solutions for objective measurement of live animals.

Six months in, we’re well advanced with the build. We now have a Marbl™ sensor for beef, and this will be integrated into a modified crush. Testing to prove the use on live cattle is planned for November 2023 – February 2024. We’ll be cross-referencing our live measurements with IMF at slaughter across different cattle breeds following 100 days and 300 days on feed.

This project highlights the versatility of our Magnetic Resonance technology. It can be used for lamb and beef, and it can be used for hot or cold non-destructive grading. Lamb carcasses are graded hot at the end of the slaughterfloor in our automated equipment – the ‘hot’ measurement gives processors grading information at the start of manufacturing and opens the door to sorting and manufacturing by grade. Taking the same technology further back in the value chain, onto the farm/feedlot, to inform producer decisions gives a significant point of difference as an IMF measurement technology that can both grade hot carcasses and measure live animals.

inMR is delighted to be able to bring a mature and proven technology to new applications. We do so thanks to our deep understanding of Magnetic Resonance and materials handling equipment.

We’ll be sharing results from our Live Cattle trials next year, but please contact us sooner if you’re interested in learning more.

Ovation NZ partners in ground-breaking research of IMF measurement programme

3 March 2023

Ovation New Zealand Ltd (Ovation) is partnering with inMR Measure Ltd (inMR) to test the development of an Intramuscular Fat (IMF) lamb grading technology, with support and co-funding from the Ministry for Primary Industries’ Sustainable Food and Fibre Futures (SFF Futures) fund.

New sensor tool helps to measure eating quality in sheep meat

21 April 2023

Developed by inMR Measure, the Marbl™ technology tool uses a single-sided nuclear magnetic resonance sensor alongside the longissimus muscle to capture IMF measurements. The sensor tool can be installed into existing carcass handling equipment to measure hot carcasses.

Ovine IMF measurement production prototype

3 March 2023

AMPC worked with inMR Measure to design and build a prototype system for non-invasive, automated, percentage intramuscular fat (IMF) measurement of lamb and to prove application in processing plants.

Prototype Single-sided NMR for non-destructive IMF measurement

29 June 2022

This project developed, tested and delivered positive proof-of-concept that an NMR configuration suitable to use on uncut lamb carcasses has shown potential to provide this measurement.

IMF of primals – end of processing line measurement using NMR - stage 2

29 June 2022

AMPC partnered with inMR Measure to trial a magnetic resonance sensor to conduct intramuscular fat measurements (IMF) of sub-primal cuts in a beef boning room.

Bovine IMF measurement production prototype stage 1

25 June 2021

This project funded the investigation of how Nuclear Magnetic Resonance (NMR) technology can be extended and implemented to measure beef carcasses in a meat processing plant